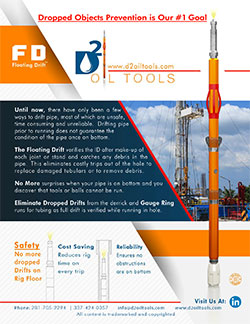

The Floating Drift is our flagship product which offers a new approach to pipe drifting in offshore drilling operations. This innovative tool addresses common challenges in oilfield completions by verifying pipe ID after the make-up of each joint or stand and catching debris in real-time.

The Floating Drift has undergone over a year of field testing on active rigs, demonstrating its effectiveness in real offshore drilling scenarios. It offers a practical solution for ensuring clear pathways for tools and balls, potentially saving time and resources in offshore operations.

For drilling organizations looking to optimize their offshore completions processes, the Floating Drift presents a tested option worth considering. It aims to provide a more efficient and reliable method for pipe drifting in challenging offshore environments.

Benefits of the Floating Drift

- Eliminates the need to drop a drift out of the derrick, preventing a possible dropped object.

- Prevents possible dropped object in well bore.

- Reduces trip times when the need to drift out of the derrick arises (Running ball drop packers, gravel pack assemblies, TCP assemblies or any other BHA).

- Allows the operator to know immediately after the joint/stand has been made up, if there is a damaged tool joint or debris in the pipe.

Download Brochures

The Floating Drift is field proven and used on rigs in the GOM and on shore locations. This tool was developed out of need from actual problems during rig operations that ended up costing millions of dollars to the operators over

the years.

Can be used to drift the drilling risers while running. After running in the hole with production tubing, there is no need to run a gauge ring prior to performing slickline work, saving time and money.

If pumped down hole, it is easily fishable, millable and can be reversed out to surface with catch tool.

No special subs need to be placed in tubing string.

Eliminates the cost and time to Pickle the Pipe Prior to Frac Pack or Gravel Pack as the drift and junk basket removes the pipe dope.

Contact Us for More Information About the Floating Drift